The high load capacity of

automobile ball bearings is a crucial feature that makes them suitable for various automotive applications.

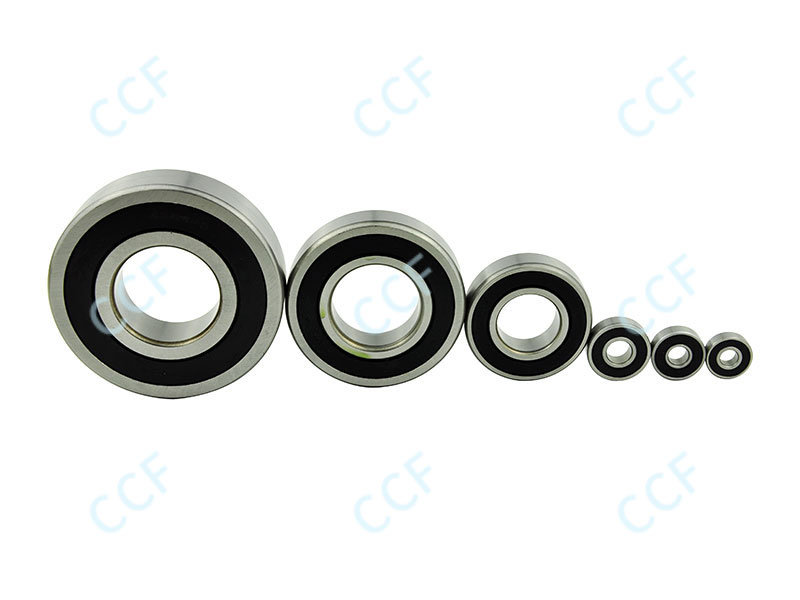

Multiple Contact Points: Ball bearings consist of multiple rolling elements (balls) that distribute the load over a larger contact area compared to some other types of bearings. This distribution of load helps to reduce the stress on individual contact points and allows the bearing to support higher loads.

Axial and Radial Load Capacity: Ball bearings are designed to handle both axial (thrust) and radial (rotational) loads. This dual-load capacity makes them versatile for applications in the automotive industry where forces act in different directions.

Precision Design: Ball bearings are precision-engineered to ensure uniform size and shape of the balls, as well as precise alignment of the races. This precision design helps distribute loads evenly, preventing uneven wear and maximizing load capacity.

High-Quality Materials: Automotive ball bearings are typically manufactured from high-quality materials, such as chrome steel or stainless steel, which offer excellent strength and durability. This contributes to their ability to withstand high loads without deformation.

Heat Treatment: Many ball bearings undergo heat treatment processes to enhance their hardness and resilience. This makes them resistant to wear, which is particularly important in high-load situations where friction and wear are more pronounced.

Cage Design: The cage or separator in ball bearings helps maintain even spacing between the balls. This prevents them from rubbing against each other, reducing friction and allowing for higher load capacity.

Lubrication: Proper lubrication is essential for reducing friction and wear in ball bearings. Lubricants help maintain the separation between rolling elements, ensuring smooth operation even under heavy loads.

Dynamic and Static Load Ratings:

Automobile Ball Bearings are rated for both dynamic and static load capacities. Dynamic load rating indicates the maximum load a bearing can handle while in motion, while static load rating indicates the maximum load it can withstand while stationary.

Advanced Engineering: Advances in materials science and engineering have led to the development of specialized ball bearings, such as angular contact ball bearings and deep groove ball bearings, designed to handle specific load conditions.

AUTOMOBILE FAN, SILICON OIL CLUTCH, BEARING

AUTOMOBILE FAN, SILICON OIL CLUTCH, BEARING

Structurally, it takes into account more unexpected situations, thereby improving the efficiency of the fan clutch and effectively extending its lifespan.

In terms of performance, automotive silicone fan clutches can withstand greater loads and will not leak oil due to pressure.